Advanced Manufacturing

What We Do

Our collaborative production innovation hubs are at the epicenter of discovery and development of manufacturing technology and its responsive deployment.

Meet Our People

Ilse Van Meerbeek

Materials Engineer

“I am a problem-solver, and some of my favorite tools are math and science. LLNL asks hard, exciting, and important questions every day. It is very satisfying to be one of the many people who help find the answers.”

Gabriella “Bella” King

Materials Scientist

“Since joining the Laboratory I have experienced amazing opportunities to grow as a researcher and as a professional. The technically diverse atmosphere of the Lab fosters a collaborative environment that allows scientists and engineers to accomplish goals as members of interdisciplinary teams, learning and growing with each project.”

Nicholas “Nick” Calta

Project Lead

“I really enjoy working with and learning from my colleagues. I get to be part of large, multidisciplinary teams, both at LLNL and at the other Department of Energy (DOE) sites we often partner with. In those teams, I work with smart, hardworking people who are experts in a wide range of fields, and I learn a lot just being in that environment.”

Join Our Team

Join Our Team

Making Our Mark Through Game-Changing Projects

Computational Design Optimization with LiDO

Systematically designing new systems that exhibit nonlinear, transient, multiscale, and multiphysics phenomena with uncertain behavior has been a major challenge to overcome. Today, our ability to manufacture greatly exceeds our ability to design. Engineers, once merely inconvenienced by inefficient trial-and-error design, are now freed by the vast space of possible designs afforded by advanced manufacturing (AM) technologies.

The development of Livermore Design Optimization (LiDO) software is a necessity to drive future innovation. LiDO software implements high-performance computing, gradient-based optimization algorithms to design immensely complex systems.

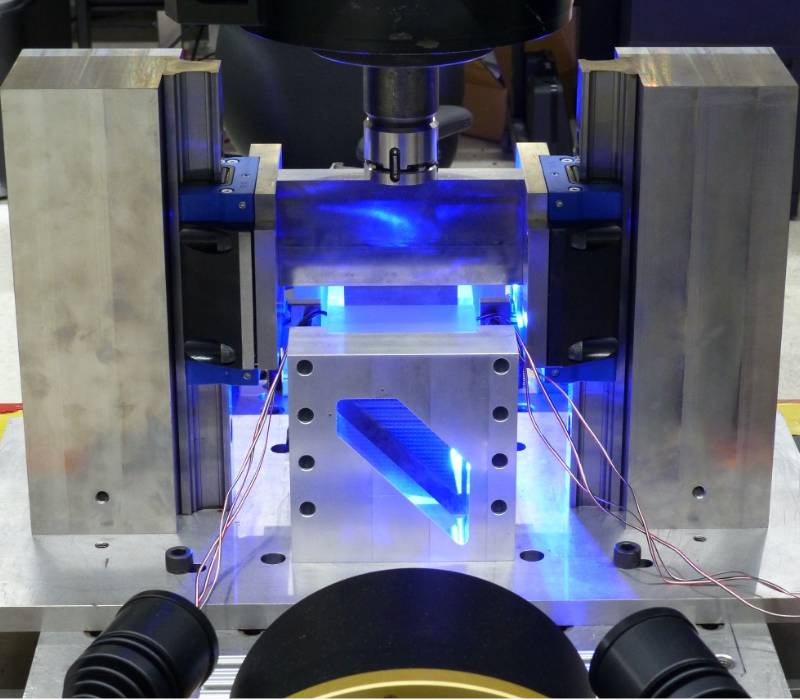

Additive Manufacturing of Metal Lattice

Additive manufacturing (AM) provides opportunities to fabricate complex structures that are otherwise impossible to produce. In the lattices project, LLNL fabricates lattice structures that have a unique combination of strength and weight, offering a wide range of potential applications for which minimizing mass is an important design parameter. Our work on lattices includes developing design tools that can be applied to optimize the tradeoff between strength and weight by tailoring the thickness of individual beams in a larger lattice part. These tools allow designers to take advantage of all the benefits of AM.

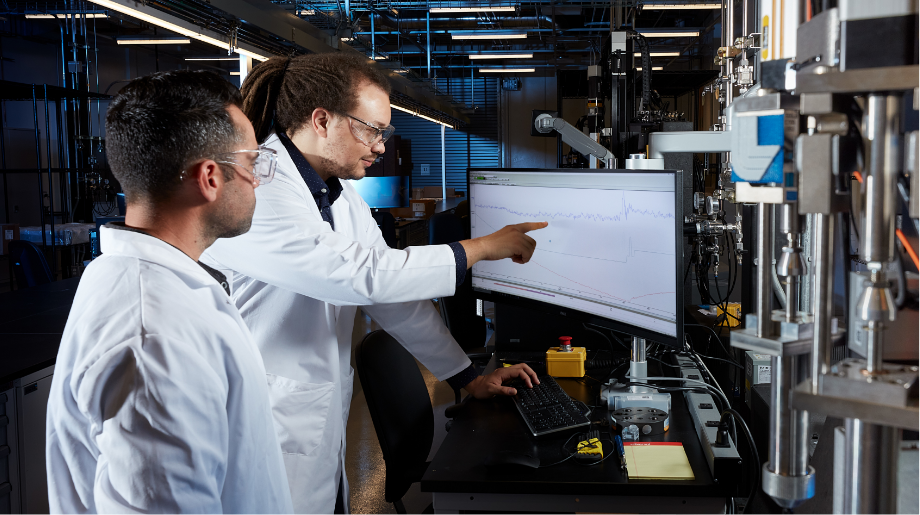

Optical Measurement for Rapid Qualification

Bringing advanced manufacturing techniques to bear on national security challenges requires more than the ability to additively manufacture a part. Qualifying and certifying parts manufactured with novel techniques is just as important as advancements in design, feedstocks, and processes. When parts are difficult to measure, this process can become a bottleneck. We are leveraging advances in non-contact optical measurement techniques like photogrammetry and structured light scanning to help facilitate the rapid, comprehensive measurements needed to qualify additively manufactured parts. These non-contact approaches show promise in speeding the qualification process.

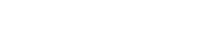

Innovative Advanced Manufacturing Labs

LLNL scientists and engineers are advancing our capabilities in advanced manufacturing (AM). Modern AM facilities allow us to apply new materials to our national security mission.

Advanced Manufacturing Laboratory (AML)

Polymer Enclave